SEDY ENGINEERING

CO

DESIGN | SIMULATION | CONSULTATION

Sustainable engineering solutions for an emerging global economy.

Sedy Engineering CO is commited to finding solutions to engineering problems in struggling communities. We believe that being part of a global community means that our solutions shouldn't come at a cost to our neighbors' way of life.

Construction Process

-Gondola and subcomponents fabricated using uPrint 3D printers

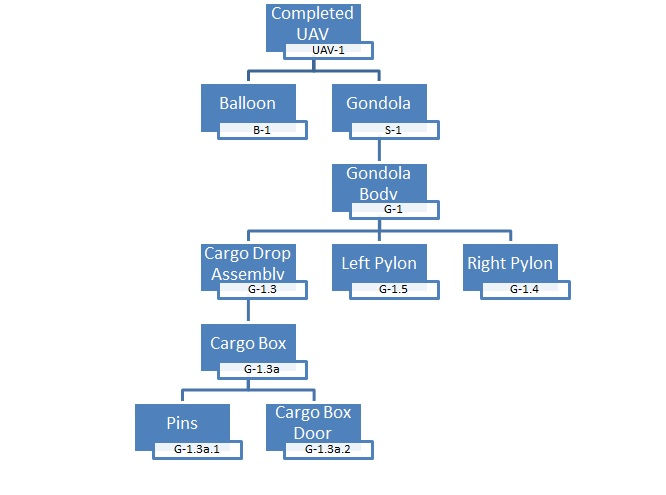

-An assembly made up of three main parts and one sub assembly - the base, two detachable motor pylons, and the cargo drop subassembly that interfaces with the gondola

-Pylons and Cargo Drop Assembly attach to the gondola via friction fits

-Cargo Drop door attaches to the container by means of a plastic nub on each door that fits securely in an indentation in the cargo box

-Servo is fastened to the interior wall of the cargo box using small bolts

-Motors are pressed into receptacles and bolted in

-Switches are mounted to the gondola using included screws

-Receiver, motor controllers, and batteries are not restrained within the gondola

Manufacturing Issues

-Friction fits between gondola and pylons too tight

-Externally mounted switches desired after Gondola was printed

-No place for motor leads to enter the gondola

-Servo would not fit into cargo drop box because there was not enough clearance for the wire

-Servo arm unable to be adjusted after installation

-Nuts used to mount servo to cargo box were too big

-Motor controller not shipped with proper connectivity hardware

-Motors did not come with mounting hardware, no mounting hardware available locally

-Propeller mounting hole too small

-Propellers too large to fit within safety shroud

Manufacturing Solution

-Dremel tool used to remove small amounts of material

-Dremel tool used to create mounting points

-Small holes drilled under pylons to allow motor leads to pass through body

-Small slot created to allow wires to pass through during installation

-A small hole was created in the cargo box opposite from the servo arm to allow access

-A small amount of material was machined off one side of each nut so they would fit next to the servo

-Connectors were created from blade-style female connectors

-Thin gauge wire used to secure motors in motor receptacles, motor can still be removed if needed

-Hole was machined to 4mm

-Jig was created to allow each propeller to be trimmed precisely